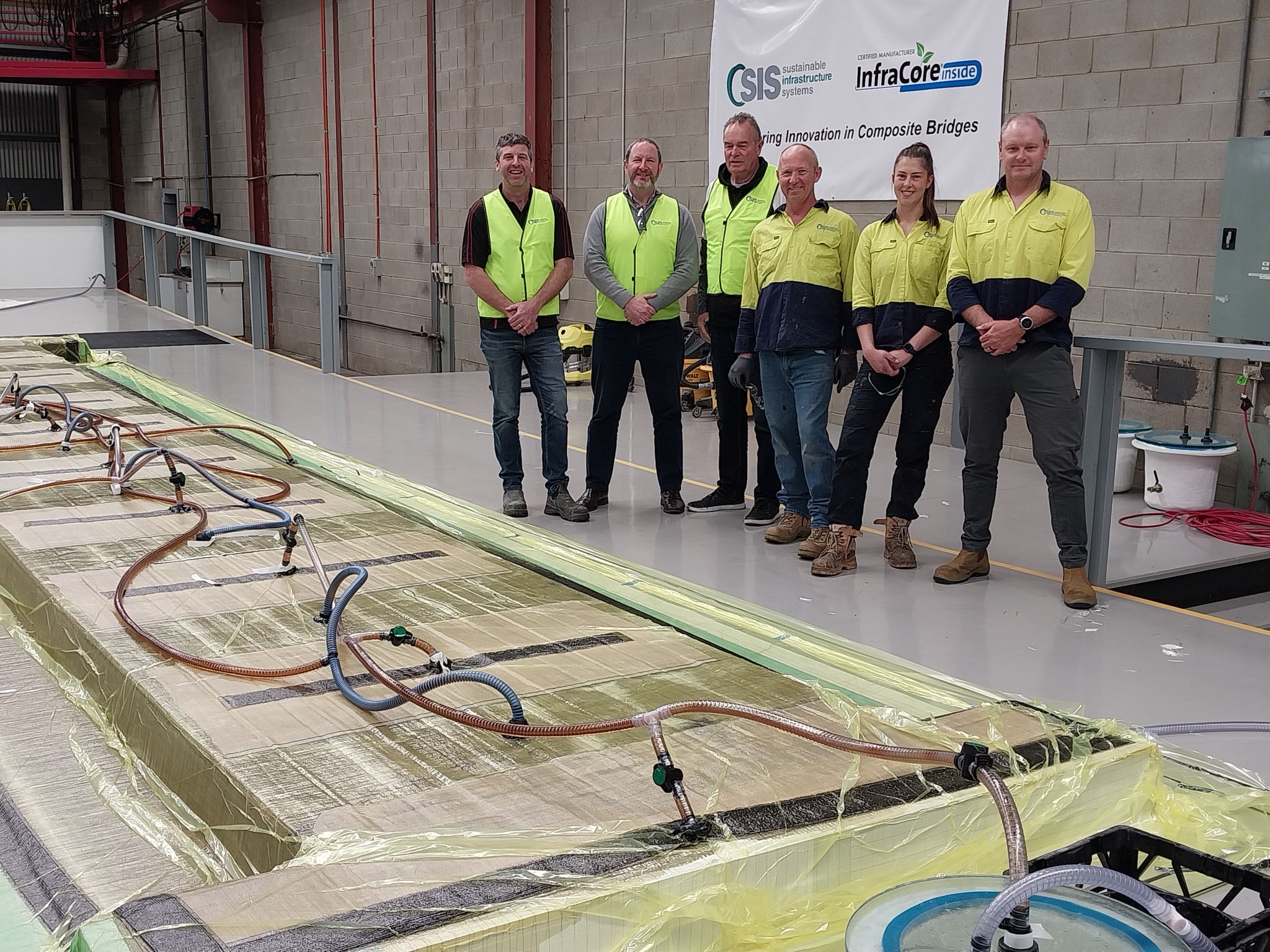

Recycled plastic will be used in the manufacture of lightweight pedestrian bridges, jetties and ultimately wind turbine blades in a new cutting-edge $1.2 million manufacturing plant opened in Wingfield.

Managing director of Sustainable Infrastructure Systems (SIS) Nick Wotton said the new plant officially opened by Trade and Investment Minister Nick Champion today, has an exclusive licence with Dutch firm InfraCore to manufacture, distribute and install its products throughout Oceania.

“Aside from creating employment opportunities with up to 15 new jobs in the first 12 months, cutting-edge technology used in the material will be a game changer in the way bridges and other structures are manufactured and installed in Australia, New Zealand and the Pacific Islands,” he said.

“We are also making a commitment after completing engineering studies to move to manufacturing bridges with a core made up of at least 50 per cent recycled plastics as of June 2023 – with a goal to move to 100 per cent over the calendar year.”

Already environmentally friendly, the structures ranging from pedestrian walkways to high-volume traffic and harbor bridges are already installed in Australia, Europe and the United States using fibre-reinforced polymer.

“This makes them lightweight and incredibly strong, allowing for spans of up to 36 metres with a 100-year design life and maintenance-free system,” Wotton said.

“Now, we’re looking to introduce bio resins and natural fibres.”

The company has ambitious growth plans with Wotton projecting turnover of $15 million by 2025.

Wotton previously owned Cosset, a company that manufactured recycled wood plastic composite fencing posts, one of its contracts involved supplying products to a Jane Goodall Institute chimpanzee sanctuary in the Congo.

The company also installed Australia’s first entirely recycled composite pedestrian bridge in the east park lands near Victoria Park in 2010.

SIS moved to Wingfield in January to build the new 1800msq manufacturing facility with Wotton saying it was important to be “bringing manufacturing back to South Australia”.

“We believe that having spent almost 30 years in sustainable infrastructure we believe the timing is right and the support is there from local, state and federal governments, along with the private sector, to be investing here,” Wotton said.